Safety Concerns in Single-Axis Tracker PV Plants: Risks and Mitigation Strategies

Safety Concerns in Single-Axis Tracker PV Plants: Risks and Mitigation Strategies

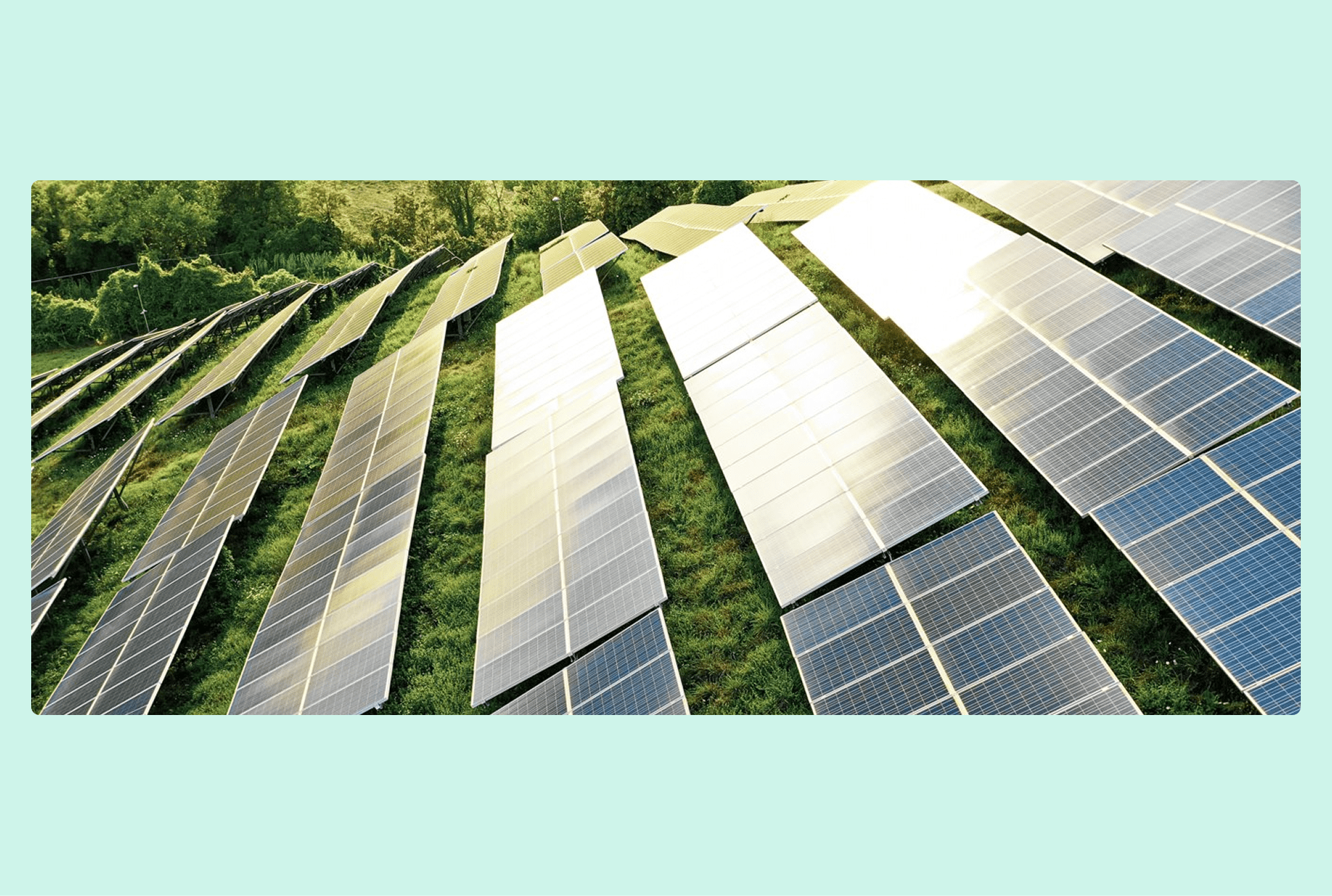

Single-axis trackers (SATs) have become a game-changer in solar PV projects. By following the sun’s path, they can boost energy output by 15–25% compared to fixed-tilt systems. But with this gain comes added complexity—and unique safety challenges that every solar professional should be aware of.

Why Safety is Critical

Unlike fixed structures, SAT systems are dynamic. They rely on actuators, sensors, and control systems to rotate panels throughout the day. This movement—combined with high-voltage DC circuits and exposure to harsh environments—introduces risks that can impact workers, equipment, and project reliability.

Environmental risk

– High Winds: If stow mode fails during storms, trackers can twist, bend, or collapse.

– Snow & Ice Loads: Extra weight can strain motors, bearings, and structures.

– Extreme Heat & UV: Accelerates wear on actuators, controllers, and cables.

– Dust & Sand: Infiltrates gearboxes, increasing friction and failure rates.

– Wildlife: Birds nesting on structures, rodents damaging cables.

Mechanical & Electrical Risks

– Mechanical Hazards: Unexpected tracker movement, pinch points, wind damage.

– Electrical Hazards: Cable fatigue, DC arc faults, poor grounding.

– Control Failures: Sensor errors, motor malfunctions, stow mode failures.

How to Mitigate These Risks

– Lock-Out/Tag-Out (LOTO): Before maintenance, ensure trackers cannot move.

– Emergency Stops: Install accessible emergency stop buttons on every row or block.

– Cable Management: Use UV-resistant, flexible carriers to reduce stress on wires.

– Routine Inspections: Focus on bearings, actuators, sensors, and electrical joints.

– Wind Stow Protocols: Implement automated systems with manual overrides.

– Fire Prevention: Arc detection, proper fusing, and vegetation control are must-haves.

– Advanced Weather Monitoring: Integrate high-wind alerts with automated stow protocols.

– Enhanced Sealing & Coatings: Protect motors and gearboxes from dust and moisture.

– Predictive Maintenance: Use SCADA data and AI analytics for early fault detection.

– Wildlife Management: Install protective mesh and cable armor.

Single-axis trackers help solar plants achieve higher yields and better ROI, but these benefits come with operational risks. By prioritizing design safety, preventive maintenance, and proper training, we can ensure that the future of solar tracking is both efficient and safe.

Environmental stress on SAT systems is inevitable—but design improvements, robust materials, and predictive maintenance can reduce failure ratios and ensure long-term reliability.