Features of the best wind turbines, that asset managers like when working on onshore wind assets

Features of the best wind turbines, that asset managers like when working on onshore wind assets

The selection of a wind turbine manufacturer and the type of the turbine depends on multiple factors. It is challenging to compare manufacturers and models without specific project criteria. Factors like geographic location, environment (proximity to the sea or forests), climate conditions, soil, accessibility, local support and maintenance (team and contract) and many others play a crucial role on the design and selection process.

However, there is perhaps an easier way to approach the “best wind turbine” question from a technical asset manager’s point of view. Drivers for choosing the “best wind turbine” for technical asset managers are health & safety, the accessibility inside the turbine (ladders) and space to work.

So, the purpose of this article is not to give the definite list of the best wind turbine, but rather to provide an insight on the features different models and manufacturers have, concerning the people working in them. The analysis is not based on any quantitative and qualitative data, but its an accumulation of opinions and hands-on experience from the technical teams that Greensolver deploy as a leading technical asset management company.

This article will provide a small overview of the preference of technical asset managers per onshore wind turbine part comparing Enercon, EWT, Gamesa /Vestas, GE and Senvion.

Let’s start with accessibility and climbing.

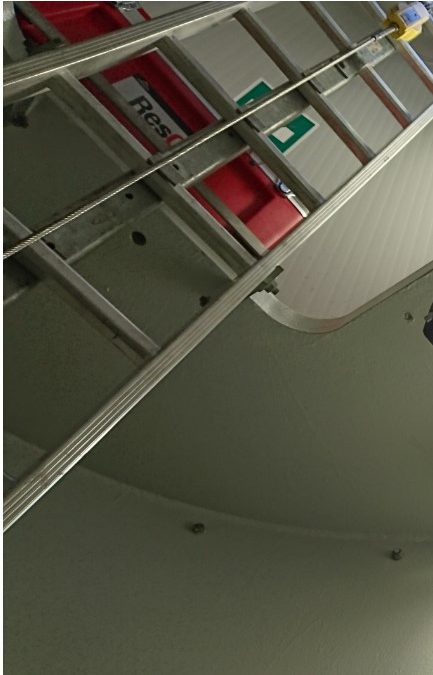

Climbing a wind turbine is highly underestimated. It is physically challenging and is more difficult in specific turbines compared to others. There are several climbing systems:

– Ladders, where you climb with your back towards the open space;

– Ladders, where you climb with your back against the tower wall;

– Ladders, with a fixed rail system for your climbing slider;

– Ladders, with a cable to attach your climbing slider. Enercon, has the most distinctive ladder in its turbines, as they use an “open ladder” approach, whereas other manufacturers have a more standard ladder design.

The Enercon ladders are offering a lot of stability and in general, the sliders work smoothly. However, they are less user-friendly if you have to climb with your hooks.

Climbing with your back against the wall is found more comfortable by most Asset Manager. However, the worker’s height determines the level of comfortability. Therefore, taller people prefer the larger Gamesa/Vestas turbines whereas shorter people enjoy the EWTs.

Ladders, where you have to climb with your back towards open space with a cable system are by far the most uncomfortable to climb.

When having the luxury option of lifts, the Avanti lifts are the most preferred. They are a bit more spacious and the safety features provide mental comfort.

After climbing the ladder, getting into the nacelle is always interesting. Every manufacturer has designed this differently, but none have managed to develop it in a way which is 100% safe or comfortable. So how did the manufactures score?

1. Enercon and EWT are found the least dangerous and most comfortable, but it is not entirely fair to compare direct drive turbines with gearbox turbines;

2. Senvion, are spacious and the entrance is not underneath a slip-ring or any other big parts;

3. Vestas and Gamesa, are quite tight to get into the nacelle and you need to be careful not to bump your head;

4. GE, provides adequate open space when climbing the last part into the nacelle.

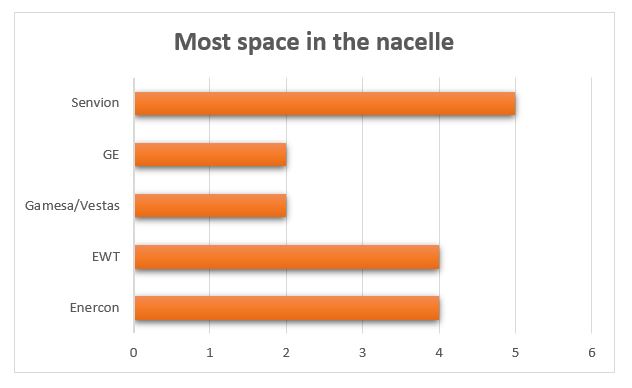

Which manufacturer provides the most space in the nacelle to walk around and work is demonstrated in the graph below, with 5 being the best score and 0 the lowest.

Whereas on the previous subject the opinions were almost unanimous, when it comes to accessing the hub/spinner, views seem to vary. Some people prefer small spaces over open spaces and visa versa.

In large extent, EWT is considered by far the easiest, most comfortable and safest turbine to access the spinner. However, Enercon is deemed to be safe, but physically demanding as you have to pull your body weight quite a lot. Gamesa/Vestas and Senvion are quite similar. You have to go through a hole. Out of the three, Senvion is slightly more spacious. However, all are found to be with hazardous confined working spaces, where engineers will have to be extra careful and any rescue attempts in case of emergency, will not be easy.

On the contrary, GE is an entirely different story. You have to climb over the roof, lower yourself down in the nose, which contains three holes, so you have to place your legs and feet carefully. Some engineers prefer this as you don’t have to deal with a confined space. Others find stepping into “nothingness” uncomfortable.

So, to conclude, is there a onshore wind turbine which engineers find most comfortable and safe to work in? It is a matter of preference and choice. People feel comfortable in different situations.

If the engineers and technicians were asked, I am sure we would pick parts from models and build our individual “ideal turbine to work in”. If only it were as simple as making your Lego one. However, one thing we do know for sure, the safer, and more comfortable to work in the turbines is, the better the performance and the care they receive maximising performance and availability.

Don’t forget the best performing turbines, are the turbines that are looked after the best!